In this opinion written by Tom Eng, TOMRA Senior Vice President and Head of TOMRA Sorting Recycling, considers how integrated flake sorting solutions pave the way to increased quality when dealing with the recycling of plastic waste materials.

OPINION: We are all familiar with the issues surrounding plastic waste. Now, more than ever, emphasis is being placed on handling this resource in a responsible and sustainable manner to ensure it can be reused. Furthermore, with new regulations being introduced around the recycled content within plastic bottles in particular, a new approach to recycling is imperative.

For this to happen though, we must implement efficient recycling processes to ensure that the plastics are handled correctly, and that we can achieve the highest possible purity.

Plant operators must opt for solutions that offer the highest levels of efficiency, which today come in the form of fully integrated pre-sorting and flake-sorting lines from a single manufacturer, rather than a mix-and-match of systems from different suppliers.

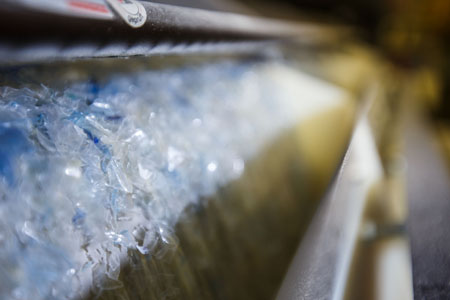

There is more pressure on plastic producers and retailers – picture flake being sorted

Recycling plants under pressure

Despite the ongoing battle against plastic pollution, the rate of plastic production continues to rise on a global scale. The latest figures suggest more than 359 million tonnes of plastic were produced for the global marketplace in 2018, a 3.2 per cent increase compared to the previous year. In total, the amount of plastic produced globally has tripled since 1990.

But the majority of this plastic doesn’t have a long-term future. In Europe alone, almost 40 per cent of plastic produced is used for food and product packaging which, in reality, is single-use plastic. Most of these products are being incinerated or disposed of in landfills. This, coupled with the fact that more than a million plastic bottles are sold every minute worldwide, means there is more pressure on plastic producers and retailers than ever before.

With this rise in throughput comes the need for efficient recycling systems to ensure all material is handled correctly and brought back into the loop.

There is also a need for higher purity when it comes to recycled plastics to ensure the material meets regulations. Recycled content laws introduced in Europe in October 2018 mean that producers must now ensure plastic bottles have a minimum of 25 per cent recycled content by 2025, so plant operators must put in place systems that can increase the purity and yield of their recycled plastics to a level that is suitable for re-use in food packaging. In the UK, HMRC has taken this one step further with its new Plastic Packaging Tax which will come into force in April 2022. This new legislation will see a £200/t tax imposed on any plastic packaging that contains less than 30 per cent recycled content.

Pledges have also been made to the Circular Plastics Alliance to increase the levels of recycled content in products. Those signing up to the initiative are taking action to boost the EU market for recycled plastics by up to 10 million tonnes by 2025.

Taking advantage of the efficiencies of flake sorting

One way in which recycling plant operators can improve the purity and yield of the plastics they recycle is through flake sorting. This can help improve the quality of output from the recycling process and can also allow for more types of plastic to be sorted efficiently, so that recycled materials can be re-integrated into the loop to help reach the recycling targets set out by the UK Government and the European Union.

Currently, there is a high demand for polyolefins, but recycling levels are still very low. Polyolefins is the collective name for materials which include polyethylene (PE) and polypropylene (PP), including different variations of the basic polymers, such as high-density polyethylene (HDPE) and low-density polyethylene (LDPE). Although the recycling market for high quality and pure recyclates has been traditionally more focused on PET, the rise in demand for recycled polyolefins signals its importance for the market – and the need to recycle these materials efficiently. In order to further accelerate recycling rates and output quality, plant operators increasingly rely on flake sorting, a technology that is already used successfully in PET recycling plants worldwide, and makes the difference between downcycling and upgrading plastics.

The flake sorting process of PET bottles consists of a number of stages: after a first stage of pre-sorting – rejecting impurities both by colour and material type, as well as a subsequent washing process – the bottles are put into a grinder or shredder and turned into flakes. Once the bottles have been shredded, the resulting flakes contain high amounts of PP/PE (which comes mostly from the bottle caps), pieces of metal, PVC from remaining labels and small quantities of other contaminants.

The flakes then go through a vigorous cleaning process which involves different combinations of metal separators, sieves and air separators – called wind-sifters – and multiple steps of flotation, hot and cold washing, rinsing and drying, all of which reduces overall contamination.

Systems which integrates pre-sorting and flake sorting ‘are advised’

Even though this process is very effective, small amounts of remaining contaminants are able to survive the process due to their size, density or magnetic characteristics. In fact, small impurities and colour deviations can negatively affect the recyclate, which will later be used to make another PET beverage bottle. Therefore, separating out all impurities to generate PET granulates that have the same quality as primary plastics should be the overall aim. A high-technology, sensor-based solution is required to purify the flakes up to the required standards and to remove any leftover contaminants. Thanks to these highly precise machines, extremely high levels of purity can be achieved, which ultimately allow for more PET bottles to be recycled and kept in the loop and out of our landfill sites.

The need for an integrated approach

However, the implementation of a flake sorting machine alone will not help improve the overall yield and purity of recycled materials unless it is part of a carefully integrated solution.

To achieve the highest purity levels, operators need a system which integrates pre-sorting and flake sorting, ideally from the same manufacturer. Pre-sorting allows plastic bottles to not only be separated from other types of plastic, but also by the colour of the material. A precise pre-sorting process is an important step because it reduces the bulk of colour and material contamination so that when the resulting bottles are shredded and turned into flakes, the amount of remaining contamination can be managed by the highly-sensitive sensors of the flake sorter, which excel in detecting and removing the small contaminant particles generated during the shredding process.

Having fully integrated systems in place to pre-sort plastics before the flake sorting begins makes it possible to fine tune both pre-sorting and flake-sorting performance as a whole according to the input material and contamination, which is crucial to improving the end result and reaching new levels of purity, while also increasing overall efficiency and yield.

By taking an integrated approach, plant operators can expect numerous benefits – both operationally and financially. An efficient pre-sorting process prior to flake sorting can help reduce the need for manual sorting as the sorting technology can remove any non-usable materials, which in turn results in decreasing operational costs – or can enable human resources to be used elsewhere within the recycling plant. In addition, by using the same supplier for both the pre-sorting and flake sorting machines, higher levels of accuracy can be achieved as the solutions are built to work in unison. With the alignment of machines, a streamlined, one-stop service and maintenance solution is achieved, which means less downtime and increased overall capacity.

Conclusion

For governments and businesses to adhere to the recycled content regulations and meet the increased demand for high-quality recyclates, a new approach to integrated recycling needs to be introduced. As such, modern, highly integrated pre-sorting and flake sorting solutions are set to be a key contributor to the future of plastic recycling.

AUTHOR: Tom Eng joined TOMRA through the acquisition of TITECH (now TOMRA Recycling) in 2004. At that time he served as Sales and Marketing Manager, and was later promoted to Sales Director. In 2012 he became Head of the TOMRA Recycling business. Mr Eng received his Master of Arts in European Business from the University of Fribourg, Switzerland. He is Norwegian and based at TOMRA’s headquarters in Asker, Norway.

The post Integrated plastic flake solutions and quality appeared first on letsrecycle.com.

Source: letsrecycle.com Plastic