Greater regulation to drive recycling and new tax incentives for producers to use recycled materials were among the policies advocated at a high-level forum at IFAT 2018, Europe’s largest trade show for the sector.

A three-hour session in the Munich exhibition centre also heard Jacob Hayler, executive director of the UK’s Environmental Services Association (ESA), praise waste management companies for tackling the consequences of China’s crackdown on imported secondary materials.

And, a European Commission official suggested EU Member States should consider using landfill tax revenue to encourage recycling.

ESA’s Jacob Hayler noted that companies had coped well with the China crisis

Much of the discussion concerned plastics and how the European Union’s newly agreed Circular Economy (CE) package of directives could be beefed up as they are transposed into the law of individual member states, including the UK.

FEAD

The event was organised by FEAD, the Europe-wide federation of waste management associations including the ESA, and BDE, the German federation for waste, water and raw material managment.

FEAD President Jean-Marc Boursier, and Anne Baum-Rudischhauser, managing director of BDE Brussels, part of the FEAD German member association, welcomed participants to the event in Munich.

Jean-Marc Boursier commented: “The theme of the day is debated at a very opportune moment: the Circular Economy Package has been adopted launching the beginning of hard work for the European Commission (EC) and Member States to ensure that the set targets are reached. In parallel, the EC is carrying out an evaluation of the Waste Shipment Regulation (WSR) which will pave the way to a potential revision of this Regulation in 2020. Furthermore, the recent measures introduced by China are a wake-up call for the European Union.”

‘Green procurement’

One of the six panellists was Helge Wendenburg, director general for water management and resource conservation for the German environment ministry, who called for ‘green’ public procurement policies by which contractors would be required to use recycled materials in their products. He argued that suppliers should be required to justify in writing why they did not do so.

Clarissa Morawski of Reloop said the Circular Economy package needed to be stronger on recycled content

Clarissa Morawski, managing director of Reloop, the Europe-wide network of organisations promoting the CE, called the EU package a “noble ambition” but she said it needed a regulated approach demanding specified minimum amounts of recycled materials, notably in plastic products and resins.

“We have to make it easier for those companies [who do use recyclates] to compete while doing the right thing,” she said.

An alternative, she added, would be low or zero VAT levied on recycled resins.

‘Bad experience’

Mr Hayler also sought smarter regulations and fiscal measures – or a combination of both – saying the UK had had a bad experience of voluntary agreements, quoting the Dairy Road Map which covered the supply chain for milk bottles which collapsed in 2015. The price of oil fell, making virgin polymers cheaper, and parts of the value chain refused to pay fractionally more to support processors recycling polymers back into domestic milk bottles.

He said the voluntary agreement was not worth the paper it was written on: “Companies went bust and it was very disappointing.”

The ESA chief also defended the need for energy-from-waste plants in the foreseeable future to incinerate materials not recycled as part of the new EU target of 65% by 2035, arguing EfW was the best process until new technologies provided long-term solutions for the treatment of residual waste.

Efforts by waste managers in the UK to absorb materials no longer wanted by China were praised by Hayler, especially as some countries such as Australia had responded by stopping collections altogether. “We’re doing a good job,” he added.

But he feared that markets could not be found for lower-quality fibre and suggested EfW could be one way of treating poor materials.

The role of waste management companies was underlined by FEAD member and fellow panellist Baudouin Ska, who said they had historically been seen as the “bad guys” but were now setting high standards and ensuring that “the border between waste and materials is disappearing”.

He urged local authorities not to panic in the face of the China ban and to trust their business partners.

“It is a difficult situation but I would say to the municipalities not to take quick decisions [about their waste contracts] by going for the lowest price,” Ska said.

Landfill tax

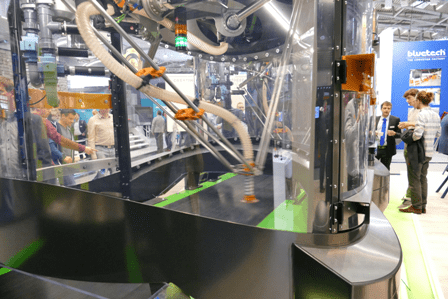

The Bollegraaf machine on show in Munich

For the European Commission, Peter Wessman from DG Environment, said the CE policies were intended to be drivers of quality. The commission was working with newer states to drive up their recycling rates and material quality through separate collections.

Asked if the commission could do more through encouraging tax incentives in member states, Mr Wessman said it already backed a number of initiatives including regional funds and innovation. He floated the idea of states using landfill tax directly to support recycling.

Both Mr Hayler and Ms Morawski spoke of innovative technologies and fresh approaches which, in future, would improve recycling.

Artificial Intelligence

IFAT is held every two years and, in the halls dedicated to sorting and other treatment of waste, the use of artificial intelligence (AI) was a strong feature.

BHS

It was Bulk Handling Systems Max AI which was one of the first with the use of such technology and latest developments were on show at IFAT along with NRT which announced the launch of its next generation of optical sorters at IFAT.

Cogni

At its stand, Bollegraaf, had unveiled its own Cogni fully automated sorting robot. The Cogni’s first public appearance follows a series of prototypes and testing during the past two years. The exhibit was set up to sort PET and HDPE but Bollegraaf says it works across the plastic grades and also paper. The model, which picks at 60-80 per minute and replaces human effort, will now be sold into the industry.

Valvan

The use of near infra red (NIR) sorting is moving into textiles. In the same hall was the Belgian manufacturer, Valvan Baling Systems, which is in a partnership to develop a market for scanning for different types of fibre once textile collectors have manually selected clothing for reuse. Using NIR, Fibersort differentiates between the different types of fibre: cotton, wool, acrylic, polyester, or even blends of these. As with other materials, items are scanned as they move along the conveyor and diverted into different bales. The current rate for the conveyor is one piece per second but Fibersort expects to increase this.

The equipment is seen as offering competitive advantage as current practice is for this major waste stream to be indiscriminately reduced to individual fibres which can be recycled into new textiles. Fibersort offers bales of specific types and colour of fibre which has greater attraction for manufacturers, including those in the car industry.

Machinex’ AI machine attracted attention at IFAT

Doppstadt

Doppstadt and Remondis have also announced a joint project to test a robotic picking system. The pilot will be assessed at Reterra, a German subsidiary of Remondis. It will sort mixed organic waste.

Machinex

The IFAT show also saw Machinex display its SamurAI sorting machine which features a four articulations robot, employing “superior artificial intelligence technology” to identify materials for an accurate, positive product recovery or a precise quality control function. The AI, explained Machinex, operates according to a pre-determined order of task hierarchy to maximise financial return while continually improving and learning from operating experience to assure maximum recognition efficiency.

The post IFAT told tax incentives would drive recycled content appeared first on letsrecycle.com.

Source: letsrecycle.com Waste Managment